The CK210B is a small CNC lathe, with KY980Tc turning CNC system(optional Siemens or FANUC system),support multi language interface display,support international standard G -code and M-code,support CAD/CAM software to make program, the standard spec includes MPG hand wheel, automatic 4 positions tool post(option 8 tools),selection of high-quality casting materials,more compact,High strength guide way, ball screw,automatic lubrication system and with flood coolant,with interlocking guard. using a single-phase 220 or 110 volt voltage,XZ axis motor type are AC servo motor, whith a 1.2kw servo spindle motor, XZ axis motor type are servo motor.Ideal for cutting aluminum alloy, brass and steel. Suitable for schools education and training, small job shop.It has several functions: turning inner and outer cylindrical surface, end surface, taper surface and thread of shaft, etc.

100mm 4 inch self-centering,optional 4-jaw chuck.Use cast iron spindle box,It has good rigidity and stability, which benefits to the machining precision.Spindle with encoder, capable of turning threads.

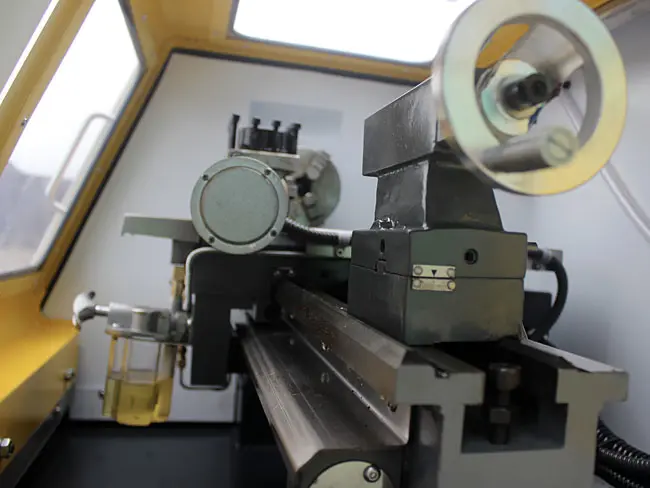

This machine is designed with a guide rail lubrication system, for extended machine lifespan.

Our large-capacity circulation cooling water tank, equipped with a filtration system, effectively dissipates heat and removes impurities, ensuring optimal performance and extending the lifespan of your tools . With manual and g-code automatic control.

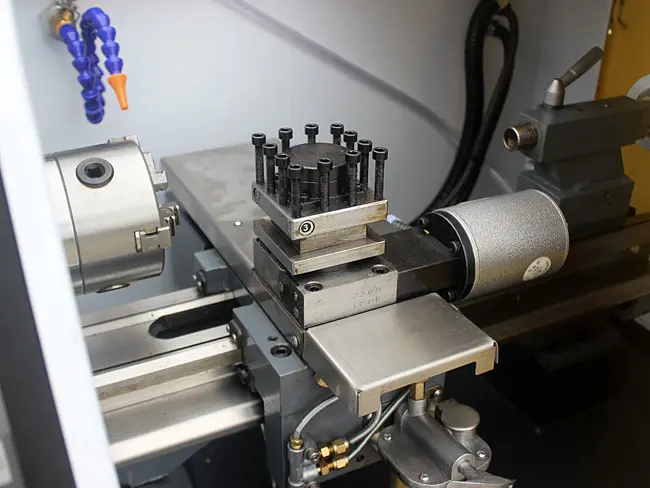

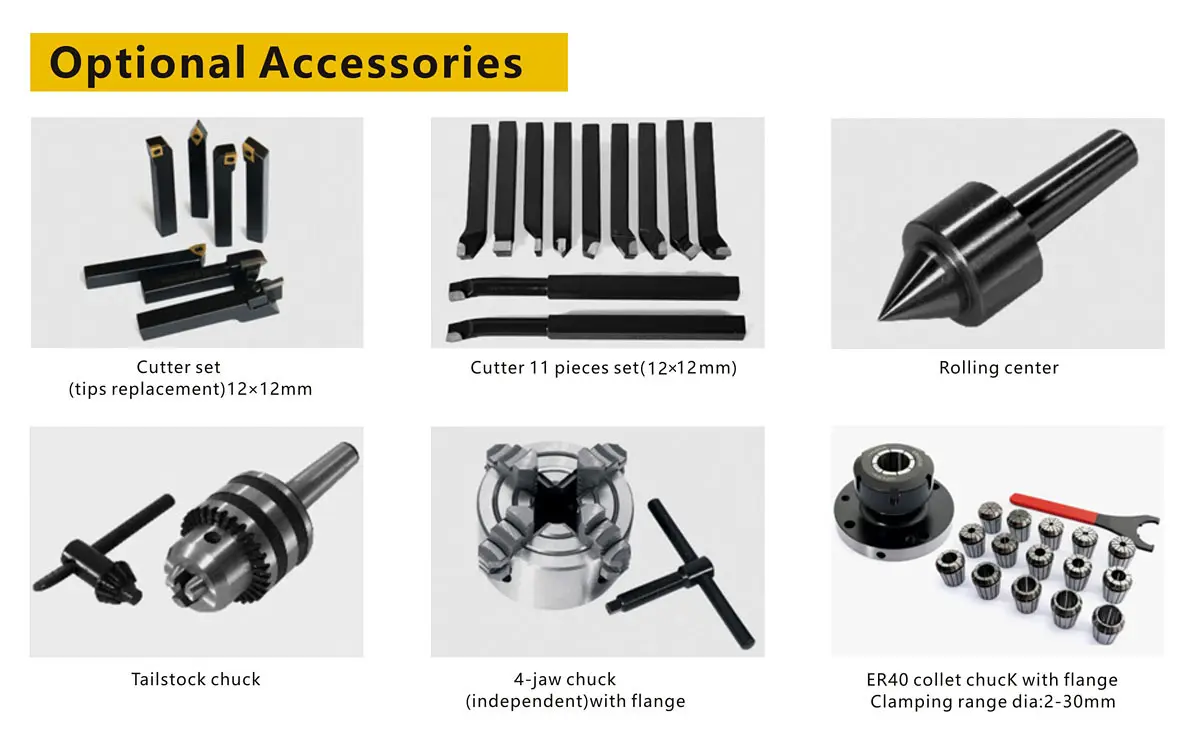

Equipped with a 4-station automatic tool change for processing more complex parts,optional 8-station automatic tool change.Turning tool specifications is 12*12mm .

Industrial Lathe CNC system,more stable and more durable, and operate more simple, while the integrated handwheel trial cutting function allows you to verify the accuracy of your program and positioning before committing to the final machining process.

Machine tool bod selection of high-quality casting materials,with lathe tailstock,semi-automatic lubricSation system,protect the rail life and ball screws for unmatched precision.

| Technical parameters |

|

|---|---|

| Turning diameter over bed(max) | 210mm |

| Chuck diameter | 100mm |

| Spindle speed | 300-1750r/min(control speed of G code) |

| Spindle through-hole | 26mm |

| Spindle mount | MT4 |

| Spindle motor power | 1100W |

| X axis travel | 90mm |

| Z axis travel | 300mm |

| X/Z axis motor | 400W Servo Motor |

| The max moving speed | 8000mm/min |

| The max feeding speed | 2000mm/min |

| Control system | YORNEW 980Tc Turning CNC System,Optional siemens 808D |

| MPG handwheel | 4 axis |

| Automatic tool change system(ATC) | 4 Tools (option 8 tools) |

| Tool dimension | 12*12mm |

| Tailstock taper | MT2 |

| Tailstock sleeve diameter | 20mm |

| Travel of tailstock | 25mm |

| Positioning accuracy: | 0.02mm |

| Repeatability accuracy | 0.03mm |

| Power | 220VAC / 110VAC |

| Weight(NW/GW) | 280/320KG |

| Overall dimension | 1170*700*1300mm |

| Packing size | 1200*860*1500mm |

CK210B Small CNC Machines of maching Video

CK210B Small CNC Machines of maching Video